What Are Wash and Wear Fabrics?

Wash and wear fabrics are innovative textiles that require minimal care after washing. These fabrics maintain their shape, resist wrinkles, and dry quickly, eliminating or greatly reducing the need for ironing. The term “wash and wear” was coined in the 1950s with the introduction of synthetic fibers like nylon and polyester. Today, wash and wear fabrics encompass a wide range of materials, including both synthetic and natural fibers treated with special finishes.

Discover the convenience of wash-and-wear fabrics at Libas-e-Noor, where style meets practicality in every garment.

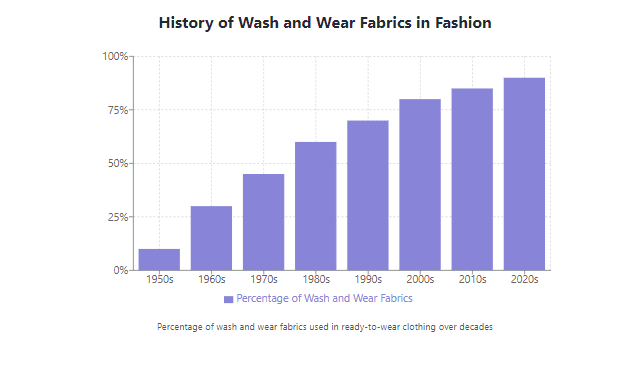

History of Wash and Wear Fabrics in Fashion

Let’s create some data about the History of Wash and Wear Fabrics in a fashion that would be ideal for a bar chart. We’ll look at the percentage of wash-and-wear fabrics used in ready-to-wear clothing over decades.

Here’s the data:

- 1950s: 10%

- 1960s: 30%

- 1970s: 45%

- 1980s: 60%

- 1990s: 70%

- 2000s: 80%

- 2010s: 85%

- 2020s: 90%

How Did Wash and Wear Fabrics Become Popular?

The rise of wash-and-wear fabrics in the fashion industry can be traced back to the post-World War II era. As more women entered the workforce, there was a growing demand for clothing that required less maintenance. The development of synthetic fibers in the 1940s and 1950s paved the way for wash-and-wear fabrics. These new materials offered properties that natural fibers lacked, such as wrinkle resistance and quick-drying capabilities.

What Were the First Types of Wash and Wear Fabrics?

The first wash-and-wear fabrics were primarily synthetic materials developed in laboratories. Nylon, invented by DuPont in 1935, was one of the earliest synthetic fibers used in clothing. It gained popularity for its strength, elasticity, and easy-care properties. Polyester, introduced in the early 1950s, quickly became a staple in wash-and-wear clothing due to its wrinkle-resistant nature and ability to hold shape after washing.

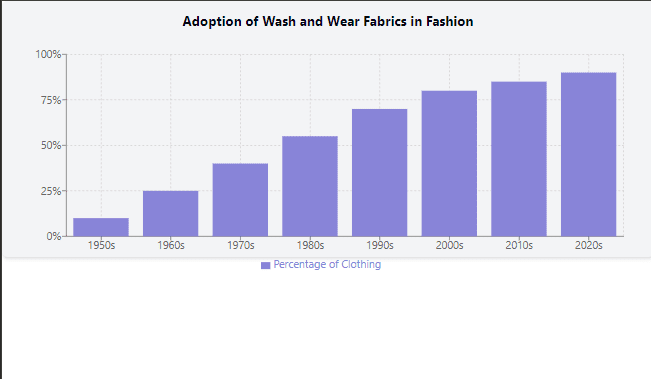

How Have Wash and Wear Fabrics Changed the Fashion Industry?

Let’s first gather some relevant data. Here’s a set of data points that would be ideal for a bar chart:

Percentage of Clothing Made with Wash and Wear Fabrics by Decade:

1950s: 10%

1960s: 25%

1970s: 40%

1980s: 55%

1990s: 70%

2000s: 80%

2010s: 85%

Convenience and Time-saving

The introduction of wash-and-wear fabrics has significantly altered consumer expectations and habits in clothing care. These fabrics have drastically reduced the time and effort required for garment maintenance, appealing to increasingly busy lifestyles. Consumers can now wash, dry, and wear clothes with minimal or no ironing, saving valuable time in their daily routines.

Sustainability and Environmental Impact

Wash and wear fabrics have had a complex impact on sustainability in the fashion industry. On one hand, these fabrics often require less water and energy for maintenance, as they can be washed at lower temperatures and don’t need frequent ironing. This reduction in care requirements can lead to a lower carbon footprint over the garment’s lifecycle.

Versatility and Durability

Wash and wear fabrics have expanded the versatility of clothing, blurring the lines between formal and casual wear. Garments that were once considered delicate or high-maintenance can now be worn more frequently and in various settings. This versatility has influenced fashion design, with designers creating pieces that transition seamlessly from work to leisure activities.

Experience the versatility of wash and wear fabrics in Libas-e-Noor’s men’s collection, where style meets functionality.

What Are the Different Types of Wash and Wear Fabrics?

Synthetic Wash and Wear Fabrics

Synthetic wash and wear fabrics continue to dominate the easy-care clothing market due to their inherent properties. Polyester remains a popular choice for its wrinkle resistance, durability, and quick-drying capabilities. Nylon is often used in activewear and outerwear for its strength and moisture-wicking properties.

Natural Wash and Wear Fabrics

While synthetic fibers initially dominated the wash and wear category, advancements in textile technology have expanded the range of natural fabrics with easy-care properties. Cotton, the most widely used natural fiber, can be treated with wrinkle-resistant finishes to create wash and wear options.

Explore the comfort of natural wash and wear fabrics in Libas-e-Noor’s cotton collection, where ease of care meets the breathability of cotton.

Blended Wash and Wear Fabrics

Blended fabrics combine the best qualities of different fibers to create wash and wear materials with enhanced performance. Cotton-polyester blends are among the most common, offering the breathability of cotton with the wrinkle resistance and durability of polyester. These blends are widely used in casual wear and uniforms.

How to Care for Wash and Wear Fabrics?

Washing and Drying Techniques

Proper care is essential to maintain the performance of wash and wear fabrics. Generally, these fabrics benefit from cold or warm water washing, which helps preserve the fabric’s shape and color. Using a gentle cycle can reduce wear and tear, especially for delicate blends.

Stain Removal Tips

While wash-and-wear fabrics are designed for easy care, proper stain removal techniques can help maintain their appearance over time. The key is to act quickly when spills occur. Blot the stain with a clean, white cloth to absorb as much of the substance as possible without rubbing, which can spread the stain or damage the fabric.

Ironing and Steaming Methods

While wash-and-wear fabrics are designed to minimize the need for ironing, occasional touch-ups may be necessary. When ironing is required, use a low to medium heat setting to avoid damaging the fibers, especially for synthetic materials. Many wash and wear fabrics respond well to steam, which can help relax wrinkles without direct heat contact.

Future of Wash and Wear Fabrics in Fashion

Technological Advancements

The future of wash-and-wear fabrics is closely tied to ongoing technological advancements in textile engineering. Nanotechnology is playing an increasingly important role, with nano-treatments being developed to enhance fabric properties such as water repellency, stain resistance, and even self-cleaning capabilities.

Sustainable Practices

Sustainability is becoming a central focus in the development of future wash and wear fabrics. The industry is moving towards more eco-friendly production methods, including the use of recycled materials and closed-loop manufacturing processes that minimize waste and resource consumption.

Collaborations with Fashion Brands

Collaborations between textile innovators and fashion brands will significantly influence the future of wash-and-wear fabrics. These partnerships are crucial for bringing new technologies to market and making them accessible to consumers.

Conclusion

Wash and wear fabrics have revolutionized the fashion industry, offering convenience, durability, and versatility to consumers while challenging manufacturers to innovate. From their origins in post-war synthetic fibers to today’s advanced blends and treatments, these fabrics have continuously evolved to meet changing consumer needs and environmental concerns.

As the industry moves forward, the challenge will be to balance the convenience of wash and wear with growing demands for sustainability and personalization in fashion.

Experience the future of fashion with Libas-e-Noor. For any questions or assistance, don’t hesitate to contact their friendly team.